Detailing

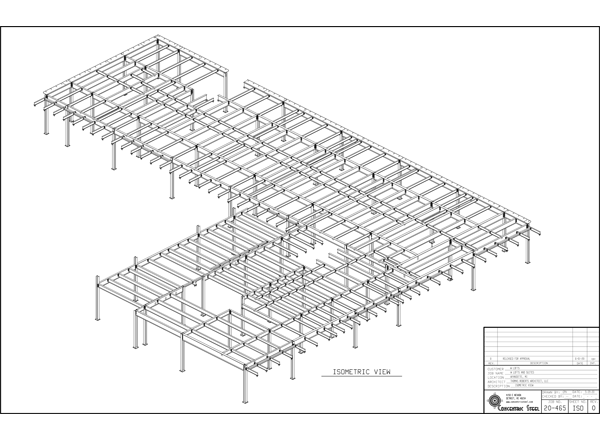

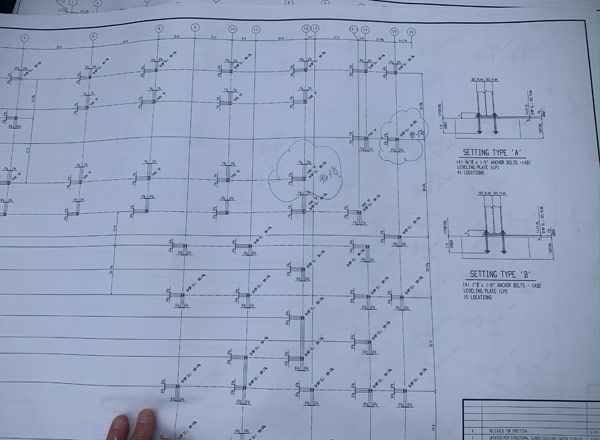

Our in-house detailing team uses SDS Modeling Software to assist customers and other trades to conceptualize the final project by viewing isometric drawings produced by the software. It also assists with overlaying our steel with other trades and providing clash detection for potential fit-up issues in the field.

By SD1 utilizing this software, it not only eliminates errors, but also expedites steel fabrication, as it creates an NC1 file that works with fully-automated equipment, which helps increase production time in the shop and eliminate human errors that could potentially affect the field during fit-up on site—impacting cost and schedule.

Shop Fabrication

SD1 works together with Concentric Steel’s design and engineering team, the 50,000 Sq. Ft. shop that sits on 2.5 acres is capable of pushing out 300 tons per week with the assistance of its fully-automated equipment: Voortman, Python and Dragon, that increase production time and eliminates errors.